Food Ingredients

TG In Cooked Ham

Biobond™TG-MG In Cooked Ham

The problem of changing raw material qualities – even within one batch – leads to high slicing losses during industrial processes and increased downtimes of the related machinery. PSE-meat – which is first visible after cooking and slicing – is a well known problem for every producer of cooked meat products.

The raw material check of pH-value is not fully suitable to detect and choose raw material for cooked ham production. As the pH-value of PSE-meat is within normal range 24 hours post mortem, this raw material contributes a problematic percentage to the final product’s composition.

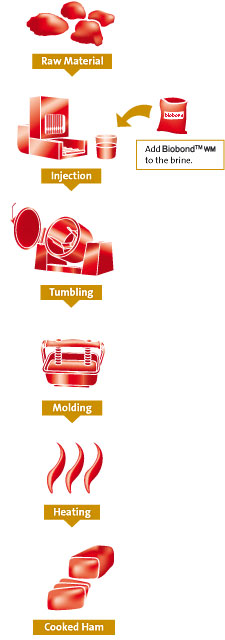

BiobondTMTG-MG helps to standardize manufacturing processes in an easy way. As a brine ingredient it is directly injected into the meat and functions as a protein network building agent during the cooking process. Trials resulted in significantly decreased slicing losses and improved slice-stability of the products produced with the help of BiobondTM TG-MG. Especially the decreasing losses of wafer-thin slices and the positive effects on the binding strength of intramuscular connective tissue provide real economic value.

BiobondTM TG-MG in cooked ham applications also helps to prevent long machine downtimes and increases customer satisfaction due to improved peelability of slices in convenience packages.

BiobondTMTG-MG standardizes production and gives your products more strength in competition.